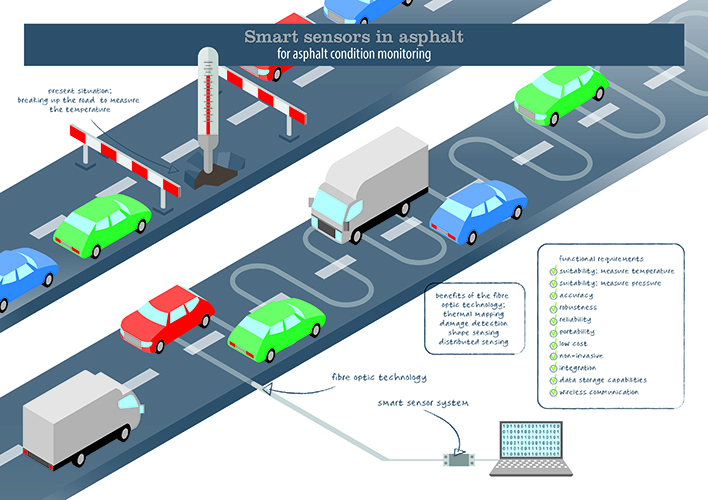

The Fibre Bragg Gratings (FBG) technology based on integrated photonics, offers specific benefits including thermal mapping, damage detection, shape- and distributed sensing. This makes it useful for determining pavement behaviour during extreme weather conditions e.g. freeze-thaw cycles when harsh winter conditions could damage the asphalt surfacing layer. However, the harsh construction environment and traffic loading highlights the high-risk challenge of installing the sensor into the asphalt layer in a non-invasive manner so that the key parameters are accurately measured during and after construction.

This project focuses on the integration of FBG into the asphalt construction process so that the technology’s benefits can be realised for constructed asphalt layers. Accurately monitoring key process parameters during and after construction using the appropriate sensor technology should contribute to extending the service life (durability) of asphalt pavements.

FBG sensors have previously been successfully used to monitor strain and other parameters in asphalt. While previous projects have mainly focused on the installation of the fibre optic technology sensors after construction has been completed, this project takes on the challenge of installing the FBG sensors in a non-invasive manner during the harsh asphalt construction process. This in itself raises significant challenges given high asphalt temperatures during construction, heavy roller compactor loading and the resulting shear stresses between aggregates which could damage the sensors during the construction process.

An initial part of the project included devising a set of functional requirements for the sensor system keeping in mind the harsh conditions that the system had to operate in during the construction process and afterwards during the service life of the asphalt layer. More importantly, to serve as a health condition monitoring system for constructed asphalt layers in the future, issues of system robustness, data accuracy, data redundancy, flexible installation and mounting, data transfer and data storage needed to be addressed in the design. To this end, several laboratory experiments were set up at Technobis, the fiber optic supplier and at local contractor, Boskalis. A first series of experiments focused on getting to know the workings of the FBG sensors and testing a few of the functional requirements in a “dry” set up. The “dry” set up typically consisted of sensors mounted inside moulds that were filled with various raw aggregates or with cold mix asphalt. This enabled checks to be made on the mounting of the sensors and the accuracy of the temperature and strain data with little danger of losing any sensors during this phase of testing. A second series of experiments focused on trialling several sensor set ups in Hot Mix Asphalt. More importantly, it focused on the protection of the FBG sensors given the very high asphalt temperatures and heavy compaction loading during construction. The protection of sensors has repeatedly been raised as a challenging issue to deal with in an extensive literature review. Several protection measures including Fibre Reinforced Polymer (FBR), steel tubing and carbon fibre reinforced epoxy resin coatings have been shown to provide adequate protection. Strain compatibility of the sensor to the package is important due to the actual strain measurement of the surrounding environment. In short, proper protection of the sensors was confirmed as key to the successful implementation of the FBG technology during both phases of laboratory testing.

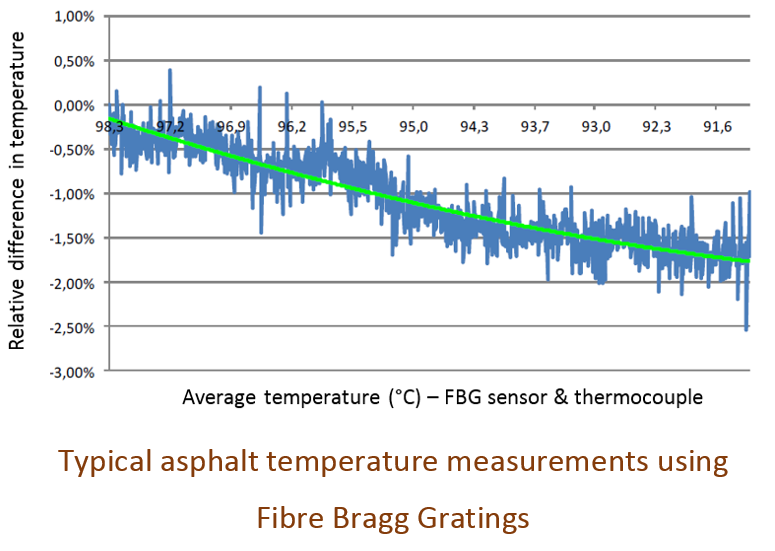

In a parallel exercise, several FBG sensors have been installed in an existing porous asphalt (ZOAB) layer at TU Delft’s linear accelerator LINTRACK facility. The purpose is three-fold. Firstly, to assess the influence of sealing fluids such as epoxy or bitumen on the accuracy of the temperature and strain measurements. Secondly, to compare the accuracy of the collected strain data with the data collected from a previously installed strain gauge. Lastly, the collected temperature data should provide more insights the behaviour of the porous asphalt layer during freeze-thaw cycles in typical Dutch winters.

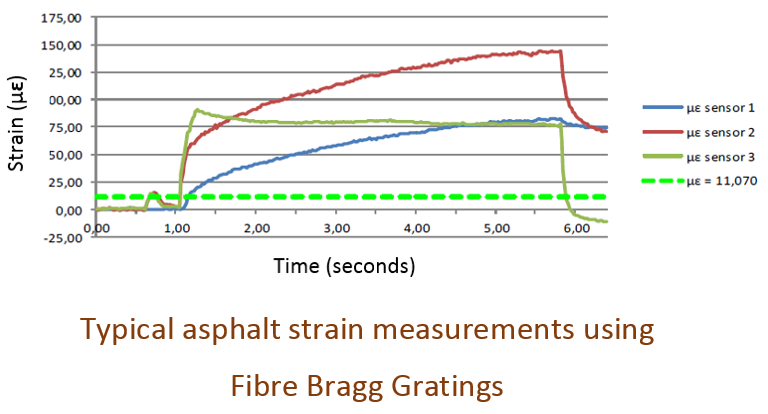

The results thus far, show that the FBG sensor is a feasible technology to monitor strain and temperature progression during asphalt construction and afterwards during the service life of the asphalt layer. The sensor is able to withstand high asphalt mix temperatures up to 200°C. It also appears feasible for accurately monitoring asphalt temperature during winter periods when freeze-thaw cycles may damage and reduce the performance of the asphalt layer. Laboratory tests using a 2ton “baby” roller compactor show that the sensor is able to deliver accurate strain measurements even under heavy loading. The strain measurements when combined with the temperature measurements, can be used to develop compaction and other performance models. Also, the strain measurements can be used to make explicit vehicle (axle) loading and therefore provide opportunities for assessing long-term damage due to for example, the overloading of trucks.

However, while the technology is promising, the study has highlighted a serious limitation. Fiber optic sensors are fragile, break easily under loading and therefore need suitable protection if they are to be installed during the harsh construction process. While several protection measures were tested during this study, more work is needed to find an appropriate protection method that guarantees the accuracy of both strain and temperature measurements. The results of ongoing long-term testing at TU Delft’s LINTRACK facility, will show whether post-construction installation has any effect on the accuracy of the collected data and whether cutting grooves into the asphalt layer after construction has been completed is a feasible method of installation for collecting accurate temperature and strain data during the service life of the asphalt layer. The study will also address issues of damage to the asphalt layer given the invasive manner of installing the sensors after construction has been completed.

Applying appropriate sensor technology in the asphalt construction process requires predictable and reproducible sensor performance given the nature of the asphalt construction process. Placing any sensor in the asphalt layer during construction is both challenging and promising. It is challenging since it needs to be done in a non-invasive manner and in such a way that it does not disturb the very properties being measured. Promising, since if done properly, it opens up opportunities for measuring a range of properties during and after construction given the rapid development of sensor technology. The benefits of thermal mapping, damage detection, shape- and distributed sensing, makes it useful for determining pavement behaviour during service life of the asphalt pavement and for working towards increasing the service life and therefore, the durability of asphalt layers. The work into studying suitable sensors, sensor modalities and wireless communication will continue given the results of this project.

Team:

University of Twente

dr. ir. Seirgei Miller, mr. Joyraj Chakraborty, Jurian van der Vegt, Daan Brinkerink

Delft University of Technology

prof. dr. ir. Sandra Erkens, dr. Xueyan Liu, dr. Kumar Anupam

Boskalis BV – mr. Berwich Sluer, dr. ir. Mohamad Mohajeri

Technobis