The current design approach for bicycle helmet liners has remained unchanged since its introduction in 1975. The majority of liners are still made from Expanded Polystyrene Foam (EPS) and while they provide sufficient protection, they have significant drawbacks. In cases of impact, the impact energy permanently deforms the EPS liner and the complete helmet has to be discarded. Furthermore, cyclists worldwide are limited to four helmet sizes based on the head circumference of standard headforms. In reality, every human head has its unique shape and dimensions. An improper fit causes discomfort and can lead to a significant reduction in head protection.

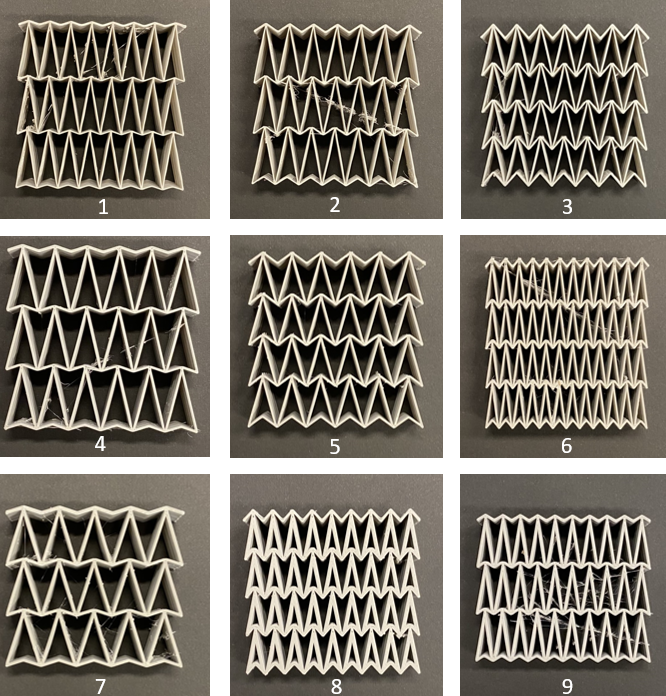

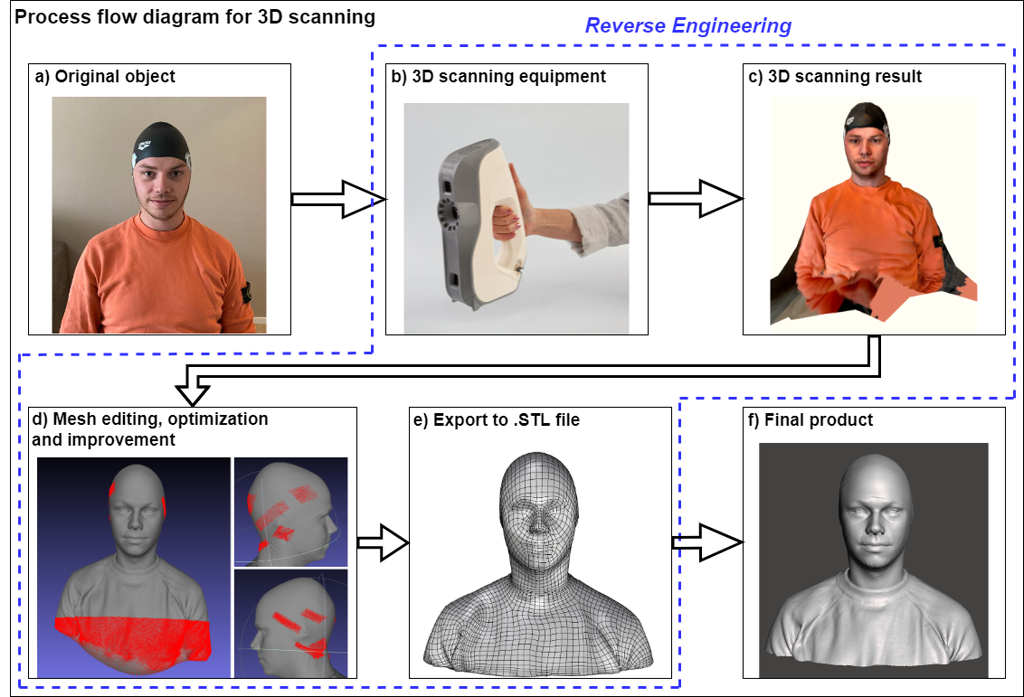

We propose an improved design for the helmet liner which overcomes the discomfort and provides a better fit. We used 3D scanning equipment to capture the unique shape and dimensions of a person’s head. For the structure of the liner, we designed an origami-based material using Grasshopper, a graphical algorithm editor of Rhinoceros. We selected and evaluated nine promising structures using Taguchi’s method. The selected structures were then additively manufactured using thermoplastic polyurethane after which they were quasi-static compressed to investigate their energy absorption capabilities. This data allowed us to choose the optimum structure and provided a viable custom-fitted alternative for the EPS liner.

This project closes the gap between metamaterial research and the complexities of designing for the human body. We believe that this approach will significantly reduce the discomfort of the current generation of helmets and improve their adoption. Additionally, the novel metamaterial based on the Miura-Ori pattern provides more scope for further optimising bicycle helmet liners.