The health industry massively contributes to the world’s pollution. It does so by emitting two gigatons of carbon dioxide into the air (4.4 per cent of global emissions). This project addresses three related problems. Firstly, why don’t we change this industry? We do not want to compromise our health or the health of our loved ones for the environment. Secondly, why are we dependent on other countries for a basic need like medical safety? The third issue addressed is the problem of misinformation. During the COVID-19 crisis a lot of masks coming from China were not of the promised quality and had to be tested in hospitals or on a national level. But what if we could make products that are safe and sustainable?

ReMask is a design in progress of a medical safety mask with an activated charcoal filter. It can theoretically filter up to 99% of particles, gases and viruses, similar to the best safety mask you can get.It will be offered with a subscription model for the filters that will be reactivated after use. It will be offered with a subscription model for the filters that will be reactivated after use.

The mask can be reused after sterilisation in the hospital itself, and the filters will not end up in landfill, but circulate between the hospitals. Locally producing the masks means independence from other countries, reducing concerns from hospitals about supply and maintenance.

The product is safe and will be certified. ReMask is a step in the direction for a more sustainable and circular health industry.

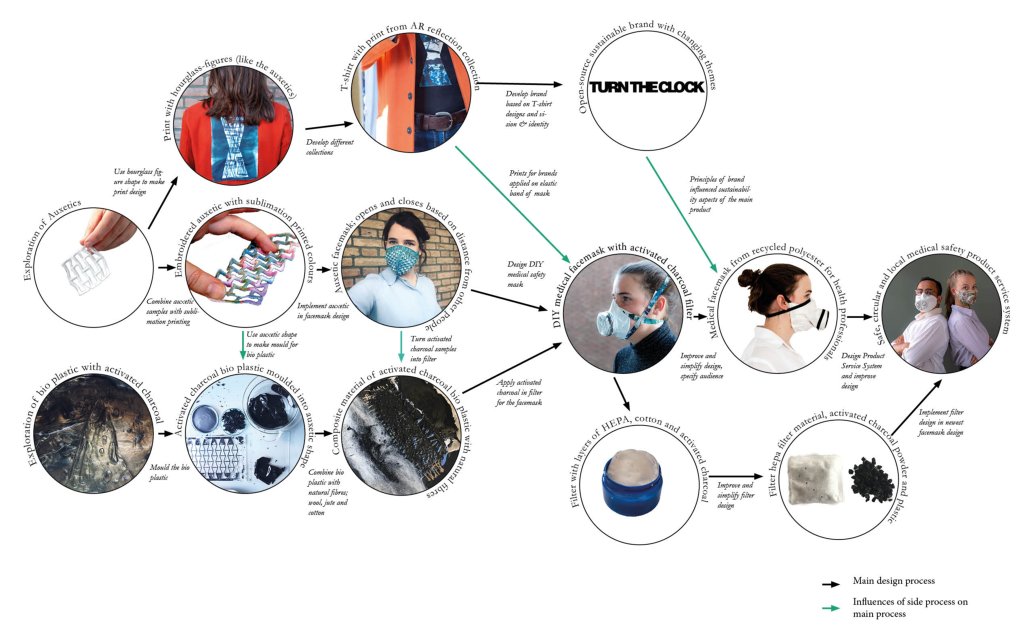

Crisis is an opportunity for change, for new ideas to be rapidly implemented into the world. The development of ReMask was a dynamic process, which evolved with the fast-changing circumstances of the COVID-19 crisis itself. It went from being a mask that could adapt itself based on external factors, to a DIY medical safety mask, to a facemask targeted towards medical professionals and finally it became a sustainable product service system of medical safety masks.

The project started from a material perspective, iterated with prototypes, while staying connected to the real-world situation of COVID-19. From talking to hospitals, medical professionals and experts, the project resulted in the development of an in-depth business plan.