Sit on a Knit

Rebekka Groeneveld, Holly McQuillan, Mariana Popescu

Making Matter: The research rethinks the applications of a well-known textile production method to develop more sustainably produced products.

Textiles surround us all. Typically, textiles are manufactured in large panels through weaving or knitting, then cut and sewn together to make our garments. Knitting, particularly 3D knitting on an industrial machine, can shape directly, thus saving material and reducing labour. Knitting allows for a wide range of material properties and aesthetics and can be integrated with other stiffer materials. The lightweight nature of the knitted fabric, combined with a structural material, allows for the development of easily transportable, large-scale objects while maintaining the advantages of 3D knitting. Can this method redefine object-making? What are the opportunities and limitations when 3D knitting a deployable object that should bear the load of a human, all through the knitting material?

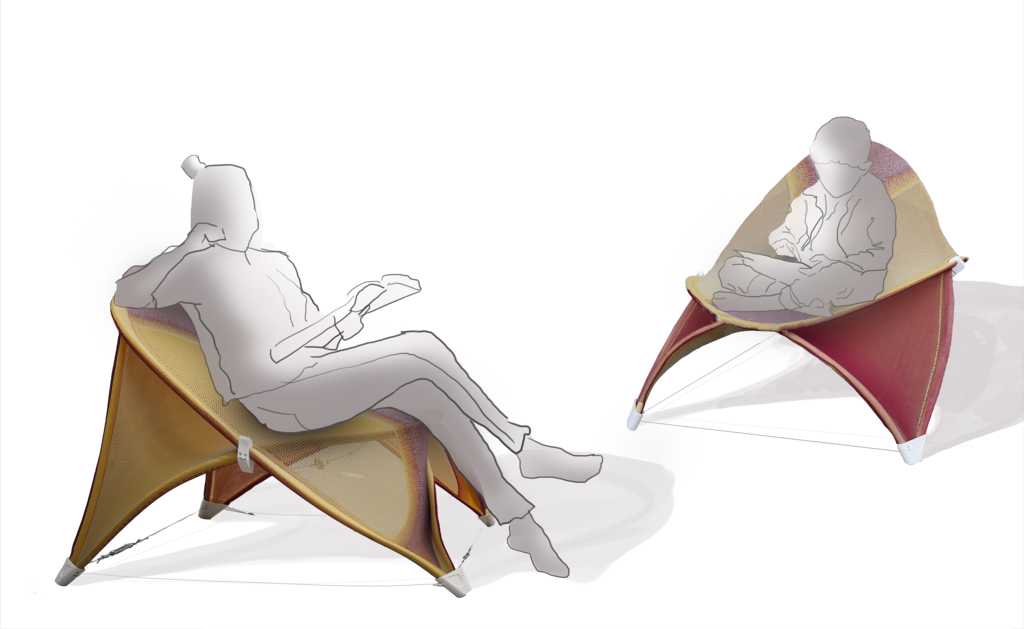

The project objective is to explore the opportunities and limitations of 3D knitting through the design of a chair. The chair should bear the load of a human and be deployable, in which the knitted material must play a key role. The research followed a Material Driven Design approach, meaning the design of the chair stems from the discovered characteristics of knitting. Form follows material.

The parameters of 3D knitting and structural materials are explored through sample making and reflecting. The process was iterative, attempting to express all the advantages and opportunities of 3D knitting as much as possible. The resulting design is a so-called textile-hybrid structure in which the tension of bent tubes balances the stretchable knitted textile. The chair is deployable, shows a wide range of knit structures and yarn materials, can be configured for eight different aesthetics, is lightweight, and produced with minimal textile waste.

The chair shows we can rethink current textile production methods to design lightweight, adaptable, deployable, industrially produced, large scale objects, minimizing the material waste and labour intensity. The form must follow from the material, not the other way around. More in-depth research is required into the behaviour of 3D knitted textile-hybrid structures, which cannot be predicted through computational modelling yet because of the complex physics of the yarn material, loop formation and internal frictions. The development of textile-hybrid objects is thus a process of trial-and-error. Research into modelling of 3D knitted textiles can broaden the range of opportunities to utilize the method for large scale objects, and reduce the material usage and streamline the production process.

#3Dknitting #knitting #textileinnovation #sustainabletextiles

Share

Contacts

- -Rebekka Groeneveldr.b.groeneveld@student.tudelft.nl