Co-Consolidated Titanium-Thermoplastic Composite Joints: a study on the mechanisms governing adhesion and durability

Vanessa Marinosci (UTwente)

The main drivers for technological innovation in the aviation industry are the reduction of the CO2 emissions along with the reduction of operating costs. Multimaterial design that joins advanced metals, such as titanium, to high-performance thermoplastic composites represents an appealing solution, as metal inserts are often required for load introduction purposes. Besides, composites and metals can be combined to form hybrid materials called Fibre Metal Laminates, typically used in fuselage panels.

The main drivers for technological innovation in the aviation industry are the reduction of the CO2 emissions along with the reduction of operating costs. Multimaterial design that joins advanced metals, such as titanium, to high-performance thermoplastic composites represents an appealing solution, as metal inserts are often required for load introduction purposes. Besides, composites and metals can be combined to form hybrid materials called Fibre Metal Laminates, typically used in fuselage panels.

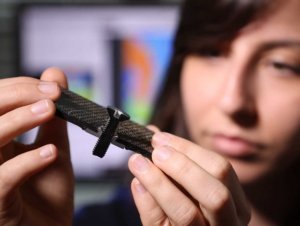

The moldability of the thermoplastic matrix allows for a cost-efficient joining method, known as co-consolidation, where composite consolidation and joining to the metal are achieved simultaneously during a standard composite consolidation or forming process.

For the implementation of the co-consolidation technology, it is essential to develop guidelines which ensure reliable and predictable metal-thermoplastic composite interfaces. Therefore, the objective of this research is to understand and optimize the interfacial bonding mechanisms between metal and thermoplastic composites, more specifically, between the titanium alloy Ti6Al4V and C/PEKK composites.

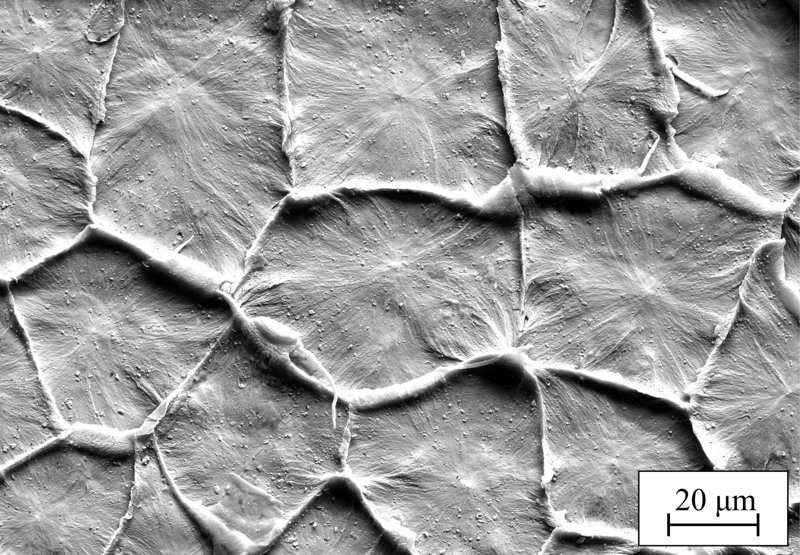

Scanning Electron Microscopy picture showing the crystalline phase of the polymer (called PEKK) on the crack surface of a titanium-PEKK joint (Picture by Nick Helthuis)

It has been demonstrated that the attraction between Ti6Al4V and PEKK relies on physical interactions. As evidence, the loss of adhesion in the presence of water is recovered when redrying. Additionally, it has been found that the mechanical interlocking, promoted by the titanium surface roughness, has a beneficial effect on the fracture toughness in dry conditions. The metal surface irregularities alter the local stress state at the crack tip and may cause a transition from adhesive to cohesive failure. A stable Ti6Al4V-C/PEKK interface in both dry and humid conditions has been obtained by combining the toughening effect of the surface roughness and the moisture barrier provided by a silane-based coating. Altogether, this work constitutes a fundamental basis towards reliable titanium-thermoplastic composite joints manufactured via a co-consolidation process.

This research was performed by Vanessa Marinosci at the ThermoPlastic composites Research Center (TPRC) and the University of Twente, supervised by Prof. Matthijn de Rooij and Prof. Remko Akkerman, and financed by the Dutch Research Council (NWO). The thesis can be found here.

How to solve the autogenous shrinkage problem of geopolymers/alkali-activated concrete?

Zhenming Li (TU Delft)

Geopolymers or alkali-activated materials (AAMs), as eco-friendly alternatives to Ordinary Portland Cement (OPC), have attracted increasing attention of researchers in the past decades. Unlike cement, which requires calcination of limestone, AAMs can be made from industrial by-products, or even wastes, with the use of alkali-activator. The production of AAMs consumes 40% less energy and emits 25-50% less CO2 compared to the production of OPC.

Geopolymers or alkali-activated materials (AAMs), as eco-friendly alternatives to Ordinary Portland Cement (OPC), have attracted increasing attention of researchers in the past decades. Unlike cement, which requires calcination of limestone, AAMs can be made from industrial by-products, or even wastes, with the use of alkali-activator. The production of AAMs consumes 40% less energy and emits 25-50% less CO2 compared to the production of OPC.

'How to solve the autogenous shrinkage problem of geopolymers/alkali-activated concrete?'

Innovative Materials, Volume 3, 2021, p. 35 (Pdf file)

(In Dutch: Innovatieve Materialen)

Despite the eco-friendly nature of AAMs, doubts about these materials as an essential ingredient of concrete exist, regarding, for example, their volume stability. Autogenous shrinkage is the reduction in volume caused by the material itself without substance or heat exchange with the environment. If the autogenous shrinkage of a binder material is too large, cracking might happen, which will seriously impair the durability of concrete.

The aim of the study of Dr. Zhenming Li (TU Delft) was, therefore, set to understand and mitigate the autogenous shrinkage and the cracking tendency of AAMs.

At first, the autogenous shrinkage of AAMs is studied experimentally. It is shown that self-desiccation is not the exclusive mechanism of autogenous shrinkage of AAMs. Other driving forces, such as the steric-hydration force between colloids associated with the change in ion concentrations in the pore solution, also play a role, especially in the very early age. Besides, AAMs show pronounced viscoelasticity, which means a large time-dependent deformation or creep. Based on the clarified mechanisms, two strategies are proposed aiming at mitigating the driving forces of autogenous shrinkage: internal curing with superabsorbent polymers (SAPs) and the incorporation of metakaolin (MK).

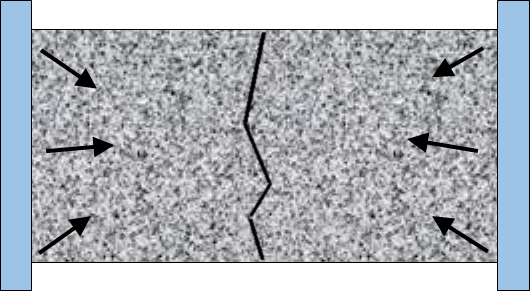

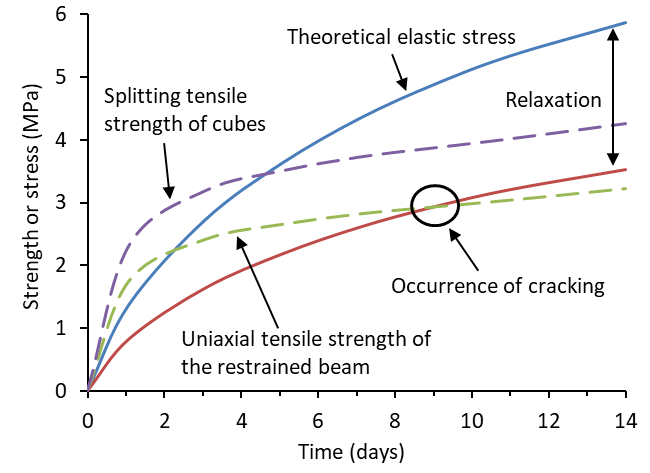

Figure 1. Schematic representation of cracking induced by restrained shrinkage.

Experiments in this study prove that the strategies proposed above are very effective to reduce the cracking tendency of alkali-activated slag and fly ash concrete. This result indicates that SAPs and MK can be promising ingredients for large-scale use in AAMs mixtures. The numerical approaches developed in this study are also useful in future studies or applications to estimate the creep and relaxation in AAMs.

Figure 2. A schematic diagram of the stress development and the resultant cracking of concrete due to restrained shrinkage.

The PhD research of dr. Zhenming Li was carried out in the Department of Materials, Mechanics, Management & Design, Civil Engineering and Geosciences, Delft University of Technology. He was supervised by dr. Guang Ye and prof.dr.ir. Klaas van Breugel. He successfully defended his thesis on the 15th of March 2021. The title of his dissertation is: Autogenous shrinkage of alkali-activated slag and fly ash materials: From mechanism to mitigating strategies.

The thesis can be found here: https://research.tudelft.nl/en/publications/autogenous-shrinkage-of-alkali-activated-slag-and-fly-ash-materia

Self-assembled Vertically Aligned Nanocomposites for Solid-State Batteries

Daniel Monteiro Cunha (University of Twente)

The need to use solid-state batteries arises from the safety problems and limitations of conventional batteries' liquid electrolytes. However, simply using solid-state electrolytes reduces the battery's specific power; that is how fast it can charge/discharge. This limitation can be overcome by employing tridimensional geometries. Daniel Monteiro Cunha focused on using self-assembled methods, via Pulsed Laser Deposition (PLD), to create Lithium-containing Vertically Aligned Nanocomposites (VAN) to form such 3D geometries for application in solid-state batteries.

The need to use solid-state batteries arises from the safety problems and limitations of conventional batteries' liquid electrolytes. However, simply using solid-state electrolytes reduces the battery's specific power; that is how fast it can charge/discharge. This limitation can be overcome by employing tridimensional geometries. Daniel Monteiro Cunha focused on using self-assembled methods, via Pulsed Laser Deposition (PLD), to create Lithium-containing Vertically Aligned Nanocomposites (VAN) to form such 3D geometries for application in solid-state batteries.

'Self-assembled Vertically Aligned Nanocomposites for Solid-State Batteries'

Innovative Materials, Volume 2, 2021, p. 36-37 (Pdf file)

(In Dutch: Innovatieve Materialen)

Lithium-ion batteries are the primary power source for many applications - from portable electronics to electric vehicles - but none of the current devices can fully satisfy all the requirements for the projected energy storage needs. Standard rechargeable batteries are based on liquid electrolytes, which limit their design and safety. Therefore, the need for all-solid-state micro-batteries arises, showing enhanced safety, volumetric energy/power density and chemical stability. These micro-batteries, developed by thin-film architecture, enables the powering of micro-scale devices, such as stand-alone sensor systems for internet of things, implantable medical devices, labs-on-chip, and credit cards. However, commercial solid-state batteries are constructed as a planar stack (two-dimensional) of thin-film layers, which exhibit undesirable energy vs power balance. This drawback can be overcome by the application of 3D geometries, increasing the internal surface area. Vertically aligned nanocomposite (VAN) thin films show such tridimensional structures. They have been developed as a new materials’ platform for creating self-assembled device architectures and multi functionalities. They show a wide range of attributes arising from the strong interplay among the materials’ properties. Highly crystalline VANs are self-assembled through PLD without control of the deposition sequence, as is required for other thin-film fabrication methods. Although various VANs have been studied in the last decade, no lithium-based VANs have yet been explored for energy storage. Considering that self-assembled VANs are obtained through PLD, the study’s main goal was to apply this principle for lithium-containing, non-toxic oxide materials and study its impact on the electrochemical behaviour for battery applications. Throughout the work, the possibility of obtaining such structures was demonstrated for various conditions. Its shape and distribution were tailored, and electrochemical analysis shows the first steps towards battery application.

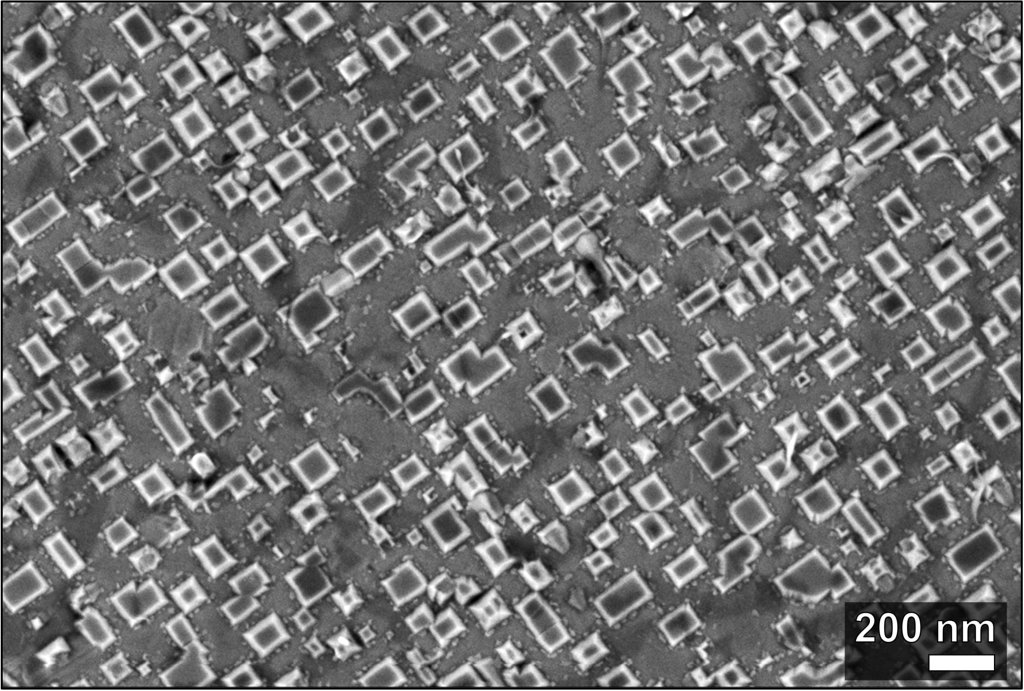

Figure 1: Top-view Scanning Electron Microscopy of a nanocomposite thin film composed of LiMn2O4 pillars embedded in an LiLaTiO3 matrix, promising solid-state battery materials.

Figure 1: Top-view Scanning Electron Microscopy of a nanocomposite thin film composed of LiMn2O4 pillars embedded in an LiLaTiO3 matrix, promising solid-state battery materials.

If this can be realized, batteries with better performance and safety can power various devices. This research made considerable steps towards this possibility.

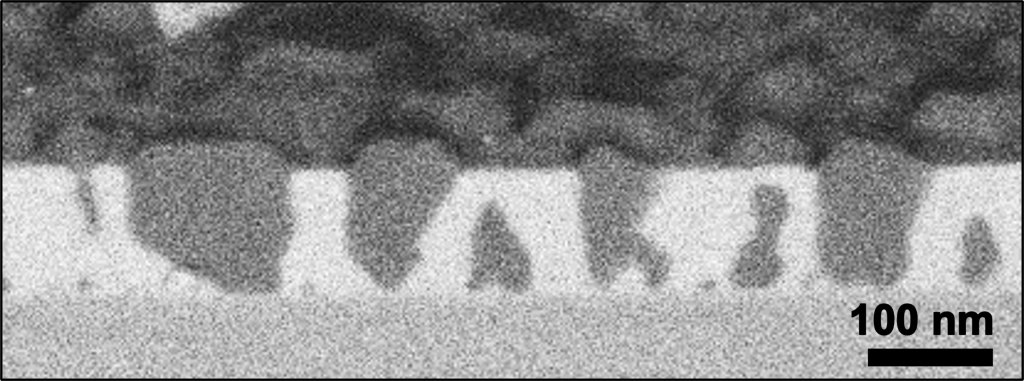

Figure 2: Cross-sectional energy selective backscattered scanning electron microscopy image showing the compositional contrast. This highlights the tridimensional geometry formation.

Figure 2: Cross-sectional energy selective backscattered scanning electron microscopy image showing the compositional contrast. This highlights the tridimensional geometry formation.

The PhD research work of Daniel Monteiro Cunha was carried out in the Inorganic Materials Science Group. His supervisors were prof.dr.ir. Mark Huijben and prof.dr.ing. Guus Rijnders from the faculty Science and Technology at the University of Twente. He successfully defended his PhD thesis on the 10th of March 2021. The title of his dissertation is ‘Self-assembled Vertically Aligned Nanocomposites for Solid-State Batteries’.

The thesis can be found here: https://research.utwente.nl/en/publications/self-assembled-vertically-aligned-nanocomposites-for-solid-state-

Artificial leaf: to capture and store solar energy

Pramod Patil Kunturu (University of Twente)

Solar technology implementation has been broadly focused on electricity generation. Despite recent progress in solar electrical energy generation, important issues remain unsolved, such as the continued need for high-power energy demand for transport, central heating, and industrial processes, and the intermittency problem, such as caused by the alternation of summer and winter periods. One of the proposed solutions is to construct a solar-to-fuel (S2F) device, which describes the concept of turning solar energy into storable fuel.

Solar technology implementation has been broadly focused on electricity generation. Despite recent progress in solar electrical energy generation, important issues remain unsolved, such as the continued need for high-power energy demand for transport, central heating, and industrial processes, and the intermittency problem, such as caused by the alternation of summer and winter periods. One of the proposed solutions is to construct a solar-to-fuel (S2F) device, which describes the concept of turning solar energy into storable fuel.

'Artificial leaf: to capture and store solar energy'

Innovative Materials, Volume 6, 2019, p. 28-29. (Pdf file)

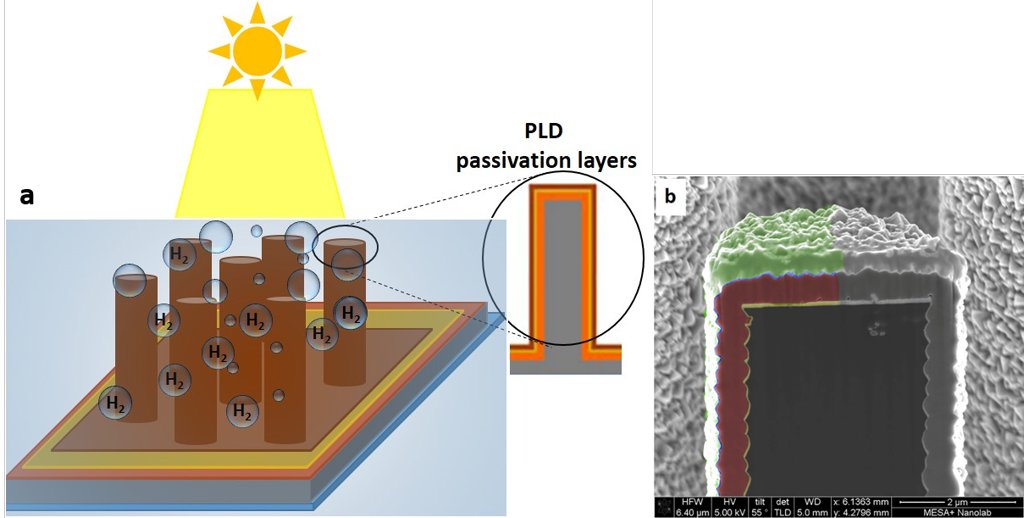

To fabricate a fully integrated, efficient S2F device based on photo-electricity, a single or set of semiconductors must be combined with a proper electrocatalyst. In this thesis, we show various geometries and materials combinations for a S2F device, primarily based on copper-based photocatalysts with structured silicon as a base material, employing device structuring and modification.

Figure: (a) Schematic diagram of sunlight driven hydrogen generation using photocathodes, (b) HR-SEM cross-section images of PLD-coated ZnO (20 nm) and TiO2 (100 nm) on top of the Si/ITO-Au/Cu2O micropillar devices. False-colored on figure indicates conformal layers (ITO/Au layer - yellow, Cu2O film - light red, n-ZnO- blue, and TiO2 - green).

In summary, the findings presented in this thesis focus primarily on copper oxides (C2O & CuO) in photocathodes. Because of its band gap of 2.0 eV, Cu2O could theoretically provide a solar to hydrogen conversion efficiency of 18% for a single junction Cu2O photocathode under established working conditions for water splitting. However, the major limiting factors are the material stability and the mismatch between the optimal thickness for light absorption and the charge carrier diffusion length. As shown in this thesis, micro/nanostructuring is favourable for enhancing the efficiency, and can provide devices that deliver higher performance compared to planar architectures.

To improve the performance of photocathodes based on Cu2O, composite materials have been used, heterojunctions have been developed, and the surface has been passivated with stable oxide materials with improved optical absorption and charge extraction properties. The tandem PEC configuration is shown to be superior, concerning aspects of high efficiency, stability, and the use of earth abundant materials. These improvements may lead to design strategies for fabricating efficient photocathodes and push the boundary of solar water splitting, possibly beyond the target of 10% solar-to-hydrogen efficiency

The PhD research work of Pramod Patil Kunturu was carried out in the department of Molecular Nanofabrication. His supervisor is prof.dr.ir. J. Huskens from the faculty Science and Technology at University of Twente. He successfully defended his PhD thesis on the 5th of July 2019. The title of his dissertation is ‘Tandem Cu2O-covered silicon micropillar photocathodes for solar-to-fuel devices’.

The thesis can be found here:

https://research.utwente.nl/en/publications/tandem-cu2o-covered-silicon-micropillar-photocathodes-for-solar-t

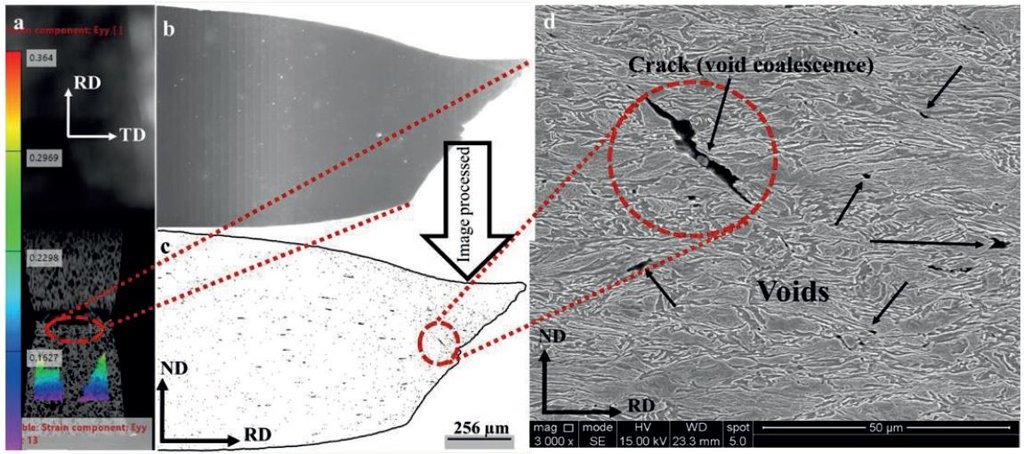

Hierarchical behaviour and failure mechanisms in automotive steel grades

Behnam Shakerifard (TU Delft)

Sheet Metal Forming is an important requirement for metal sheet to be employed in automotive applications. Many experiments and simulations are performed in order to predict the forming limits of steel sheets, which are determined either by observation of the sheets’ failure or deformation localization during various forming processes. In order to enhance the formability at the macroscopic level, a deep understanding of micro-mechanisms of failure is necessary as well as the hierarchical connection through various length scales.

Sheet Metal Forming is an important requirement for metal sheet to be employed in automotive applications. Many experiments and simulations are performed in order to predict the forming limits of steel sheets, which are determined either by observation of the sheets’ failure or deformation localization during various forming processes. In order to enhance the formability at the macroscopic level, a deep understanding of micro-mechanisms of failure is necessary as well as the hierarchical connection through various length scales.

'Hierarchical behaviour and failure mechanismes in automotive steel grades'

Innovative Materials, Volume 4 2019, p. 21 (Pdf file)

Figure: An example of damage mechanisms at different length scales which lead toglobal failure: (a) a high strain rate (687s-1) tensile deformation of a bainitic steel loaded along the Rolling Direction (RD), (b) contiguous collection of ~1000 SEM micrographs of the fracture sample in (a), (c) the corresponding image processed version of (b) with clear distribution of voids and (d) etched microstructure of the fractured bainitic multiphase steel.

In the current research work, dr.ir. Behnam Shakerifard, under supervision of dr.ir. Jesus Galan Lopez and prof. dr. Leo Kestens, investigates damage initiation micro-mechanisms under static and dynamic loading by advanced experimental characterization techniques and crystal plasticity based modelling. This research is conducted on the 3rd generation of advanced high strength steels, which are promising candidates for the production of various components of the car Body-In-White.

The topology of 2nd phase constituents at micro and meso-scale have different local and global impact in bainitic multiphase steels. It is shown that earlier damage initiation and higher volume fraction of voids do not essentially lead to earlier macroscopic failure. Moreover, crystallographic orientations susceptible to damage initiation are identified by crystal plasticity modelling and experimentally validated by scanning electron microscopy observations.

Bainitic multiphase steels exhibit a positive strain rate sensitivity, which is desirable for crash worthiness and for improving the forming behaviour. It is shown that any microstructural strengthening mechanisms in steels can decrease the strain rate sensitivity.

The PhD research work of Behnam Shakerifard was carried out at Delft University of Technology in collaboration with Ghent University. Behnam Shakerifard successfully defended his PhD thesis on 24th of June 2019. The title of his dissertation is ‘From Micro-mechanisms of Damage Initiation to Constitutive Mechanical Behaviour of Bainitic Multiphase steels’.

The thesis can be found here:

https://repository.tudelft.nl/islandora/object/uuid%3A230fffcb-b313-4f9f-bec0-e619bc62b0d4

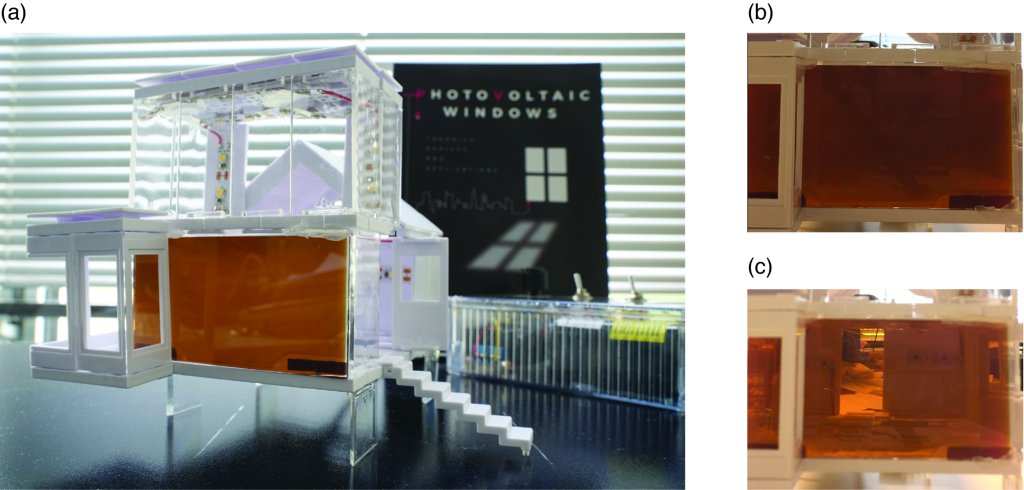

Harvesting Energy from your Windows

Yuan Gao (TU Delft)

Globally, more than a third of energy consumption is attributable to the building sector. Reducing the consumption of building energy generated from fossil fuels helps alleviate the air pollution and global warming. Some European countries regulate that all new buildings shall be nearly zero energy buildings (ZEBs) by the end of 2020. Apparently, local energy harvesting is required to realize this goal. Among all realistic strategies, building-integrated photovoltaic (BIPV) is an obvious choice for those regions with adequate solar radiation. In congested urban areas, high-rise modern buildings possess more potential for harvesting solar energy around the window areas than roofs. Therefore, innovative design is required from the cell level to the system level regarding window-integrated photovoltaics.

Globally, more than a third of energy consumption is attributable to the building sector. Reducing the consumption of building energy generated from fossil fuels helps alleviate the air pollution and global warming. Some European countries regulate that all new buildings shall be nearly zero energy buildings (ZEBs) by the end of 2020. Apparently, local energy harvesting is required to realize this goal. Among all realistic strategies, building-integrated photovoltaic (BIPV) is an obvious choice for those regions with adequate solar radiation. In congested urban areas, high-rise modern buildings possess more potential for harvesting solar energy around the window areas than roofs. Therefore, innovative design is required from the cell level to the system level regarding window-integrated photovoltaics.

'Harvesting Energy from your Windows'

Innovative Materials, Volume 4 2019, p. 25 (Pdf file)

Figures (a) - (c): (a) A demonstration house model of STPV-PDLC system. The window dimensions are around 10 * 5 cm. (b) The STPV-PDLC window reveals opaque in the “off” state when no voltage is applied to the PDLC film. (c) The STPV-PDLC window turns semi-transparent when an AC voltage is applied to the PDLC film.

Dr. Yuan Gao proposed, together with prof. Miro Zeman, prof. Kouchi Zhang, dr. Olindo Isabella and dr. Jianfei Dong, an innovative approach to collecting solar energy from window areas in buildings and meanwhile creating comfortable daylighting for human eyes. This idea is realized by designing and fabricating a semi-transparent photovoltaic (STPV) glazing window combined with a polymer-dispersed liquid-crystal (PDLC) film. The semi-transparent amorphous silicon solar cell shows an average transmittance of 20.04% with a power conversion efficiency (PCE) of 6.94%. According to the climate data of Delft, such a PCE is sufficient to power an equal-area PDLC film, which can switch from an opaque to a transparent state in a second by applying an alternating-current (AC) voltage. The prototype of a house model, containing the STPV-PDLC system, has been built to demonstrate the feasibility of such a combination.

The PhD research work of Yuan Gao was performed under the joint supervision of Delft University of Technology in the Netherlands and State Key Laboratory of Solid State Lighting in China. Yuan Gao succeeded in defending his thesis on 25 June 2019, at Delft University of Technology. The title of his thesis is ‘Photovoltaic Windows: Theories, Devices and Applications’.

The thesis can be found here:

https://doi.org/10.4233/uuid:7aa8438c-6106-4c0f-a33f-0ceb8782ad23

More: TU Delft website

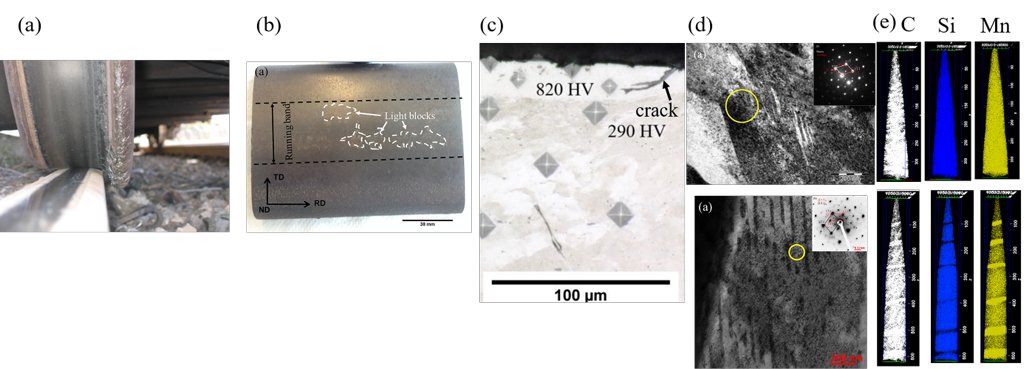

What really happens inside railways....

Jun Wu (TU Delft)

Each year, ProRail has to spend several million euros on periodic and ad-hoc maintenance work on railway tracks, in order to remove fatigue cracks before they lead to catastrophic rail fracture. One of the widely considered causes for the fatigue damage, which in railways applications occurs as Rolling Contact Fatigue (RCF), lies in the changes in the internal structure of the steel that are induced during the passage of trains: so-called white etching layers (WEL) form. The extremely high hardness of the WELs is considered to be the origin of its susceptibility to fracture and crack formation during the subsequent loading by passing train wheels. Until now, the prevalent models used to describe the RCF process in rails fail to predict the occurrence of the WEL, due to the fact that the origin and character of the WEL remained debatable.

Each year, ProRail has to spend several million euros on periodic and ad-hoc maintenance work on railway tracks, in order to remove fatigue cracks before they lead to catastrophic rail fracture. One of the widely considered causes for the fatigue damage, which in railways applications occurs as Rolling Contact Fatigue (RCF), lies in the changes in the internal structure of the steel that are induced during the passage of trains: so-called white etching layers (WEL) form. The extremely high hardness of the WELs is considered to be the origin of its susceptibility to fracture and crack formation during the subsequent loading by passing train wheels. Until now, the prevalent models used to describe the RCF process in rails fail to predict the occurrence of the WEL, due to the fact that the origin and character of the WEL remained debatable.

'What really happens inside railways...'

Innovative Materials, Volume 2 2019, p. 35. (Pdf file)

Figures (a) - (e): Railway steel at different length scales. From left to right: (a) macroscopic view of the rail/wheel contact at the metre scale; (b) signs of WEL formation at the rail surface, seen at the millimetre scale; (c) microscopic cross-section of railway steel, where the hard (820 HV Vickers hardness) WEL, as well as a fatigue crack, is visible at the top at the micrometre scale; (d) nano-twins and cementite traces in the WEL’s martensite at the nanometre scale; (e) distribution of alloying elements C, Si and Mn at the nanometre scale, with the WEL in the top three pictures and the original steel in the bottom three.

Dr. Jun Wu explores, together with prof.dr.ir. Jilt Sietsma and prof.dr.ir. Roumen Petrov, the root cause of the WEL formation via a series of microstructure characterizations, laboratory simulations, and theoretical modelling. The microstructural study, combining a wide variety of modern microscopy techniques, leads to the unambiguous conclusion that the WEL forms due to the significant heat generated during the wheel passages. The microstructure changes show that underneath train wheels the temperature repeatedly increases to over 700°C. The WEL structure was successfully reproduced under well-controlled laboratory conditions mimicking this rapid temperature rise followed by fast cooling. Furthermore, the characteristics of the WEL formation process were studied by phase field modelling. The insight provided by the thesis work of Jun Wu provides important guidance for the future design of new rail steels with higher resistance against WEL formation.

The Ph.D. research work of Jun Wu was performed under the joint supervision of Delft University of Technology and Ghent University. Jun Wu succeeded in defending his thesis first at Ghent University on 7 November 2018 and later, on 17 December 2018, at Delft University of Technology. This entitles him a joint degree from both universities. The title of his thesis is ‘Microstructure Evolution in Pearlitic Rail Steel due to Rail/Wheel Interaction’.

The thesis can be found here: https://doi.org/10.4233/uuid:c536ca47-8981-4a9e-916f-396bcbca4bc5

TU Delft website:

First joint PhD degree Materials Science TU Delft and Ghent University

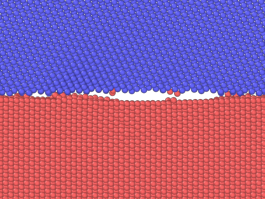

Nano-scale failure in steel

Astrid Elzas (TU Delft)

Multiphase alloys such as advanced high strength steels can show unexpected failure due to dislocations piling up at internal boundaries between the soft iron matrix and the hard precipitates. The stress concentrations caused by the dislocation pile-ups might trigger interface decohesion followed by the formation of voids and, eventually, macroscopic cracks. To prevent such material failure, accurately predictive material models are needed.

Multiphase alloys such as advanced high strength steels can show unexpected failure due to dislocations piling up at internal boundaries between the soft iron matrix and the hard precipitates. The stress concentrations caused by the dislocation pile-ups might trigger interface decohesion followed by the formation of voids and, eventually, macroscopic cracks. To prevent such material failure, accurately predictive material models are needed.

'Nano-scale failure in steel. Interface decohesion at iron/precipitate interfaces' Innovative Materials, Volume 1 2019, p 35. (Pdf file)

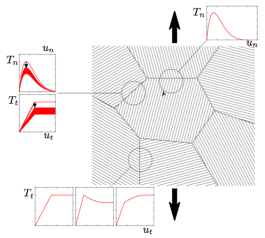

Dr.ir. Astrid Elzas studied together with Prof.dr. Barend Thijsse crack nucleation and interface decohesion on the nanoscale with large-scale molecular dynamics simulations, to understand which conditions lead to interface decohesion. Systematically varying different physical parameters allowed clear observation of the important physical effects in a controlled manner. Not only where the studied interfaces and the numbers of dislocations piling-up at the interfaces varied, also different loading modes where considered. Apart from pure shear and pure tensile loading, in this study also mixed loading, i.e. a tensile force under an angle with the interface, was considered. It is found that the interface structure, which changes during response to loading, is the key factor determining the material response.

Apart from the deeper and systematic understanding of interface decohesion resulting from this study, also interface/material-specific traction-separation relationships are developed which can be applied in larger scale material models to improve the accuracy of this models with respect to the description of interface behaviour and with that lead to a better prediction of material failure.

Figure 1: Molecular dynamics simulation of interface decohesion at an interface between the soft iron matrix (red) and a hard precipitate (blue) of steel.

Figure 2: Schematic representation of various interfaces subjected to different loading modes, due to their orientation. Various relations between tractions and separations are found for the different interfaces and different loading modes.

On 10 January 2019 Astrid Elzas obtained her Doctorate cum laude for her thesis “Nano-scale failure in steel” at Delft University of Technology.

The thesis can be found here: https://doi.org/10.4233/uuid:f72f61f4-4508-4552-85b8-d89abbbee90e

Source: TU Delft

'Co-Consolidated Titanium-Thermoplastic Composite Joints: a study on the mechanisms governing adhesion and durability'

'Co-Consolidated Titanium-Thermoplastic Composite Joints: a study on the mechanisms governing adhesion and durability'