In the past year both of them received a grant from the European Research Council: Prof. Jaap den Toonder a Proof of Concept grant, and Dr. Yoeri van de Burgt a Consolidator Grant. Common thread in their work is the microfabrication lab (Microfab/lab) at Eindhoven University of Technology, where a colorful collection of materials and manufacturing techniques fuels a successful research program at the interface of materials science and biological systems. The laboratory will be thoroughly renovated this year. In their temporary lab, the two researchers talk about their work.

Text and interview: DBAR science writer & editor

Photos: Bart van Overbeeke Fotografie

(A Dutch version of this interview is available here: Microfabricage op het grensvlak van materiaalkunde en biologie.)

Temporary cleanroom

In the Microsystems section, innovative technological concepts and manufacturing methods for microsystems are developed towards a wide range of applications. The work is often inspired by biological concepts, and the newly developed microsystems are applied, for example, to understand biological processes important for health and disease. “All disciplines can be found here: from materials to devices to systems, even algorithms and biology. All these topics interest us,” says Van de Burgt. The groups are connected by the shared Microfab/lab, packed with microfabrication techniques for research relevant to a wide range of applications. The lab has been under renovation since the beginning of 2024. Van der Burgt: “The renovation will take a year. But as experimental groups we cannot wait that long. That is why a temporary facility with a cleanroom and other laboratory spaces was built. In just a few months, it’s been done very quickly.”

Open lab environment

What characterizes the Microfab/lab? Den Toonder: “People who come to visit us, including colleagues from abroad, often say: gosh, there are so many different things in one place here. Our lab brings together all kinds of manufacturing technologies. From cleanroom facilities for microfabrication to femtosecond lasers, 3D printers, to mechanical machining. It is rare to combine so many techniques in one lab. Diverse but also coordinated and connected. This makes it logistically very easy to combine various manufacturing steps. But it also means that you meet a lot of different researchers who can inspire new ideas.” Both researchers emphasize that the threshold for using the lab is kept as low as possible. Den Toonder calls it an ‘open lab environment’.

Antibiotic resistance

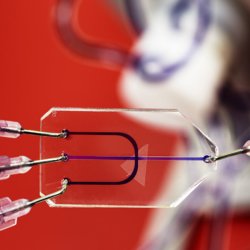

The concepts developed in the Microfab/lab are diverse. Den Toonder: “On the one hand, we develop materials and devices to control or study biological processes. And on the other hand, we use biology as inspiration to design and develop our devices.” Den Toonder's desk features a colorful collection of devices, of all kinds of shapes and made from all kinds of materials. Enthusiastically he picks a few of them. “Take this thin disk, for example, in which we bring liquids into contact with each other to determine the antibiotic resistance of bacterial infections. We drip a small amount of urine into the reservoir in the middle. The liquid spreads via radial channels to reaction chambers where not only nutrients are available for the bacteria, but also detectors that reveal the presence, the metabolic effect, of bacteria. Within an hour you can see, at a glance, which antibiotics are most effective for this specific patient. The fabrication process, using hot embossing, and the materials required are all quite simple. The challenge was to design the fluidic process. A start-up from our group is now working to further develop the device.”

'Cancer on a chip'

Another example that Den Toonder shows is a rectangular piece of rubbery polydimethylsiloxane or PDMS. “If you look closely, you will see two white areas of a millimeter in size inside the transparent PDMS. Cancer cells can be placed there.” On the outside, the chip is equipped with connection points for liquid pumps. “We use this chip to investigate the spread and metastasis of cancer. For example, how does such a cell pass through the wall of a blood vessel? How does it depend on the structure and stiffness of the material? What is the role of biochemical conditions, such as different oxygen concentrations? We can set all these factors precisely in this 'cancer on a chip' system. Because the PDMS is transparent, we can follow the movement of the cancer cells with microscopes.” This type of device, with the collective name 'organ on a chip', is Den Toonder's specialty. His ERC grant (see box) is aimed at pumping fluid around in these chips using cilia, just as is done inside the human body.

Neuromorphic engineering

Yoeri van de Burgt uses the Microfab/lab to build electrical circuits inspired by how the brain works. He calls both this research and his research group Neuromorphic engineering. “The brain is very good at a number of things such as recognizing patterns and faces, learning, data processing. Computers can do those things too, but they also use a lot of energy. We build circuits that can learn from organic material, from plastic, so to speak. They learn by themselves, so not via an external computer. We try to come up with smart applications for these simple circuits. Consider, for example, a robot that learns to find its way through a maze. Such a robot is not a complete brain, of course, but it does learn. Or a biosensor that learns to recognize certain disease substances in a drop of sweat. These are very nice applications of mechanical engineering, materials science, and algorithms. It all comes together.”

Programmable microcircuits

The secret of Van de Burgt's self-learning circuits are mixed organic conductors: polymers that conduct both ions and electrons (or holes). With an electric pulse on a separate gate electrode, more or fewer ions can be drawn from an electrolyte into the polymer structure, permanently changing the conductivity of the structure. Using these conductors, the researchers can build programmable microcircuits. “These programmable conductors are actually artificial variants of the synapses that provide connections in the brain,” says Van de Burgt. “We can use them to build neural networks that learn like a brain learns, without being connected to an external computer.” He imagines such self-learning circuits in cameras or sensors that do not need to be connected to external computers. “If you drive your self-driving car somewhere in the desert, it still has to be able to use the information from its sensors intelligently.” With his ERC grant (see box), Van de Burgt wants to use this self-learning ability to make the connections between artificial electronics and biological systems 'smart'.

Material development

Although both Van de Burgt and Den Toonder are mainly working on devices and less focused on fundamental material development, materials science is never far away. Van de Burgt: “I would like to improve the stability of my organic materials. They are sensitive to oxygen. And the programmed conductivity does not remain forever. Another materials science challenge is in manufacturing the circuits.” Because the polymers are soluble in water, conventional lithography techniques cannot be used for building multi-device circuits. “We now stack two non-conductive parylene layers with a kind of soap in between. We then punch holes in the top layer, which we fill with conductive polymer. Finally, we peel off the top layer. Quite some work, especially if you want to make larger circuits. In recent years we have been working hard on a method to make water-soluble polymers resistant to standard lithography steps.” Den Toonder: “A similar material development is also needed to build better 3D printers. The resolution of these printers is determined by the material properties of the ink, and there is still much room for improvement. It would help us enormously.”

What is the 4TU dimension of the work in the Microfab/lab?

Van de Burgt indicates that his group uses polymers from Groningen, and Den Toonder explains that his organ-on-chip work is strongly nationally oriented, coordinated by the Human Organ and Disease Model Technology (hDMT) consortium. “Together with partners throughout the Netherlands, we are developing a general platform in which all kinds of organ-on-chip techniques can be combined. The platform itself is being made in Twente. In Eindhoven we make all kinds of chips that fit on that platform. And in Delft work is being done on the sensors that we want to integrate onto the platform. As universities of technology, we could also try to do everything ourselves, but I think it is better if each university focuses on its own strengths and then works together. The 4TU platform is, perhaps also unconsciously, ingrained in the minds of many people. Thanks to 4TU.HTM we can find each other more easily.”

Material-specific learning

Van de Burgt emphasizes that there are many similarities between the 4TU partners, for example because they use the same materials, such as the electrically conductive polymer PEDOT:PSS or nanoparticles, or because they study similar systems. “We have good contacts, but a large collaborative project would be welcome. There are many opportunities for collaboration. I would like to link the biological sensors from Delft with my learning systems. We all use organic PEDOT:PSS. Or take on an even more fundamental challenge with Groningen and Twente: can we tailor the learning theory of learning systems to the material that needs to learn? Every material is different, but the learning theory is basically always the same. It is a bit of a 'holy grail' if we could use the material properties to make the learning process more efficient. For example, if you want to implement a non-linear activation function in a neural network, you can do this very efficiently with a material that responds non-linearly to external impulses. The algorithms do not yet take this into account. We could pioneer that in a 4TU context.”

Big event

Back to the Microfab/lab, which is currently being renovated completely. Den Toonder: “Basically everything will remain the same, only better and brand new: air treatment, electrical installation, climate control, fume hoods, infrastructure for gases, and so on. That will help our research tremendously.” Until then, Den Toonder, Van de Burgt and the other Microsystems groups will have to use the temporary lab. Van de Burgt: “It already looks beautiful from the inside, but I think everyone will be happy when our own lab opens again.”