After four years of doctoral studies at Wageningen University & Research, food technologist Dr. Emma Hinderink recently started as a postdoc at TU Delft. “It was quite a transition. While in Wageningen we always talk about the protein transition to save the world, in Delft it's mainly about the energy transition.” Yet that change of perspective was exactly what Hinderink was looking for after her successful research into protein emulsifiers for mixing foods. She said goodbye to the proteins from Wageningen but continues mixing the immiscible in Delft.

Text and interview: DBAR science writer & editor

Photos: Emma Hinderink & Karin Schroën

(A Dutch version of this interview is available here: Het onmengbare mengen.)

Stabilized drops

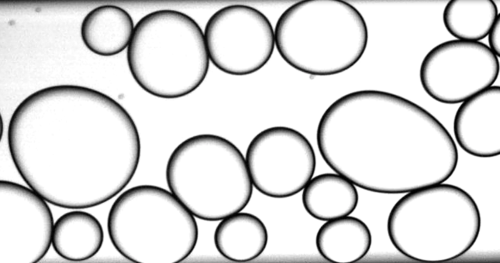

What do milk and bitumen have in common? Like countless other liquid, viscous or spreadable products, they are mixtures of liquids that are in fact immiscible. By surrounding drops of one liquid with a stabilizing layer of so-called emulsifiers, they can be neatly distributed over the other liquid, creating a stable emulsion. Hinderink: “In Delft we look at the fluid dynamics of these emulsions. What happens to the drops as they’re undergoing rather rough process steps? They can deform, merge, disintegrate or form groups that move collectively. It's a rich dynamic.”

Ideal replacement

“I worked on emulsions in Wageningen as well, but these were emulsions in foodstuffs such as dairy products. They mainly rely on protein emulsifiers derived from milk. In the context of the protein transition, there’s an intense search going on for plant-based alternatives.” In principle, plant proteins are abundant: they can be obtained from numerous sources such as legumes or seaweed. But can they also be used as emulsifiers in foods? Hinderink: “Milk proteins are unsurpassed in their functionality as emulsifier. Completely replacing them with plant proteins will therefore not be easy. I looked into the possibilities of using mixtures of plant and animal proteins. As a step in the right direction.”

Doubts

Hinderink focused specifically on proteins extracted from peas. As emulsifiers, these do not perform as well as milk proteins, but also not so bad that they cannot be put to good use. How well would a mixture of the two types perform? While her supervisor Karin Schroën (see box) hoped that, in the right blend, the proteins would reinforce each other, Hinderink had her doubts whether the mixtures would be a success. “Above all, they were fascinating systems to work on because of their complexity. The proteins in the mixtures were so different from each other that unravelling their interactions brought us all kinds of fundamental insights into the behaviour of proteins in emulsions. Those fundamental aspects are what motivates me. I want to know exactly what happens and why, so that I can apply that knowledge to other systems."

Miniature laboratories

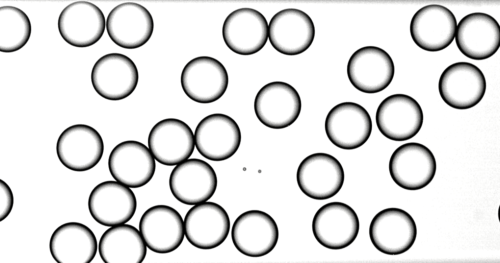

An innovative aspect of Hinderink's research was the use of microfluidic test systems: channels of a tenth of a millimetre in diameter through which the emulsions flow. Using cameras, the stabilized drops can be tracked one by one. “Food production often takes place in large stainless-steel kettles full of opaque white mixtures. Good luck trying to see what’s happening inside: they are 'black boxes'. Both the channels and the liquid streams in our miniature laboratories are so thin that light can pass through them. This allows us to study both the emulsification process and the stability of the formed droplets using light microscopes.” Hinderink was the first to look at the deformability of protein-stabilized droplets on very short time scales, down to tenths of a second. “The emulsification process starts very quickly after you put the liquids and emulsifiers together. What you see happening on the scale from minutes to hours and beyond originates in the first milliseconds. If you understand those first moments, you can further improve the process.”

Coalescence

What happens in those first moments? “We saw that the milk proteins immediately coated the oil droplets in water, while the pea proteins took about a second. If both species were present at the same time, the pea proteins initially hindered the network formation, but gradually a stable mixed protein layer was created.” By looking at droplets bumping into each other in microfluidic channels, Hinderink found that milk proteins protected them against coalescence better than protein mixtures. “The merging or coalescence of droplets is an essential part of the story of emulsions. For one application you absolutely don’t want it to happen, for another you do. Our measurements establish a link between coalescence and protein composition at the level of single drops.”

Soothing to watch

While simple drops have been studied using microfluidics for some time, it was completely new for food research. These materials are full of substances that seek out the droplet surface, explains Schroën. “Up until now, we mainly performed measurements on stationary model systems, and never on droplets that move in the type of liquid flows that are also present during large-scale production processes. We can mimic those flows in our microfluidic channels.” Hinderink is lyrical about the measurements. “People should see the movies of emulsions flowing through the channels. The drops deform, collide and sometimes merge, before continuing on again. It's soothing to watch. It can really make me happy. But apart from that, I think the technology can be an eye-opener for the field. It provides a wealth of new insights."

Two is a crowd

In addition to droplets flowing through microfluidic systems, Hinderink also investigated the competition between different types of proteins on stationary droplets. After droplets have been stabilized by proteins of one species, they can be displaced by proteins of another species. Hinderink discovered that proteins derived from peas were being replaced by milk proteins while, the other way around, displacement did not occur. She then showed that the former is energetically advantageous because networks of milk proteins are a lot more elastic, and thus cover the spherical droplets more easily than the stiffer networks of pea proteins. “This type of research has already been done in the 1980s, but never for mixtures of milk and plant proteins. There are such cool techniques nowadays to measure forces in protein networks, and to add different types of proteins one by one; that was not possible back then.” The phenomenon of controlled protein displacement can be used to realize mixed protein layers around droplets, with any desired composition and combination of properties.

Improving production processes

Industrial partners are extremely interested in Hinderink's research, according to supervisor Schroën. “They are open to new insights,” says Hinderink. “Every time I presented new results, they told me that they already had their suspicions. Companies have a wealth of practical experiences with emulsions; I had the opportunity to reveal what’s going on in detail.” Hinderink expects that industry can use her results to, by making small adjustments, further improve their production processes, for example to make them more energy-efficient. “In Delft, I am now working on a model system that is so general that the results should be applicable to all types of emulsions, from medicines to creams. While the oil industry is looking for ways to quickly separate mixtures of oil and water by destabilizing the emulsions, food companies want to make them as stable as possible. I hope I can provide useful insights to everyone!”

Different points of view

Now that Hinderink has moved from Wageningen to Delft, she is experiencing the type of synergy that the 4TU.Centre High-Tech Materials (4TU.HTM) also strives for. “Where I think in terms of the interfaces between materials first, focus in Delft is mainly on material properties such as their viscosity. It's tempting to get stuck in your own mindset. Bringing together different points of view is therefore extremely valuable. We open each other's eyes to new aspects of the same system.” In addition to different points of view, it is also about different measurement techniques. “In Delft, I’m learning to work with new techniques, including data analysis methods.” Already during her PhD project, Hinderink was keen to combine multiple measurement techniques in order to cover all time and length scales relevant to the emulsions. “A word of warning,” she says with a big smile, “no supervisor should ever tell you 'just go and measure it.' It easily takes over a month before you have mastered a new measurement technique.”

Now that Hinderink has moved from Wageningen to Delft, she is experiencing the type of synergy that the 4TU.Centre High-Tech Materials (4TU.HTM) also strives for. “Where I think in terms of the interfaces between materials first, focus in Delft is mainly on material properties such as their viscosity. It's tempting to get stuck in your own mindset. Bringing together different points of view is therefore extremely valuable. We open each other's eyes to new aspects of the same system.” In addition to different points of view, it is also about different measurement techniques. “In Delft, I’m learning to work with new techniques, including data analysis methods.” Already during her PhD project, Hinderink was keen to combine multiple measurement techniques in order to cover all time and length scales relevant to the emulsions. “A word of warning,” she says with a big smile, “no supervisor should ever tell you 'just go and measure it.' It easily takes over a month before you have mastered a new measurement technique.”

Temperamental

With ten papers, Hinderink's PhD project can be called a particular success. Looking back, she concludes that she was lucky. Except for the unexpected departure of her daily supervisor Dr. Claire Berton-Carabin to France, she experienced no major setbacks. Schroën was impressed by her work ethics: “Microfluidic chips are temperamental. Sometimes they act up. That can be irritating but if your name is Emma then you keep at it until everything works. Within a year she had enough data for four papers. She just didn’t leave the lab.” Hinderink: “I liked to start at 7 in the morning, so that I could work in peace for two hours before the students took over the lab. The corona pandemic meant that I finally sat down at the computer and started writing my thesis. Fortunately, my lab work had just been completed.”

Protein transition

Back to the protein transition. How does Hinderink see the transition from emulsifiers based on animal proteins to more sustainable variants? “Developments are moving fast now, but I don't think the switch will be easy. At the moment we are trying to replace one protein with another. This one-to-one approach does not make sense because animal and plant proteins have incomparable functionalities. No plant protein can compare to milk proteins. In the words of Einstein: “If you judge a fish by its ability to climb a tree, it will live its whole life believing that it is stupid.” I think we need to let go of this approach. Instead, we need to focus on the unique capabilities of a specific plant protein and exploit those. That means we have to formulate products differently and adapt processes.” For the time being, it is not Hinderink who’s working on this challenge - but never say never. “Wherever I go, Claire [Berton-Carabin], Karin [Schroën] and I will make up some excuse to stay in touch. And to do a project together again.”